Saving Costs in Product Development

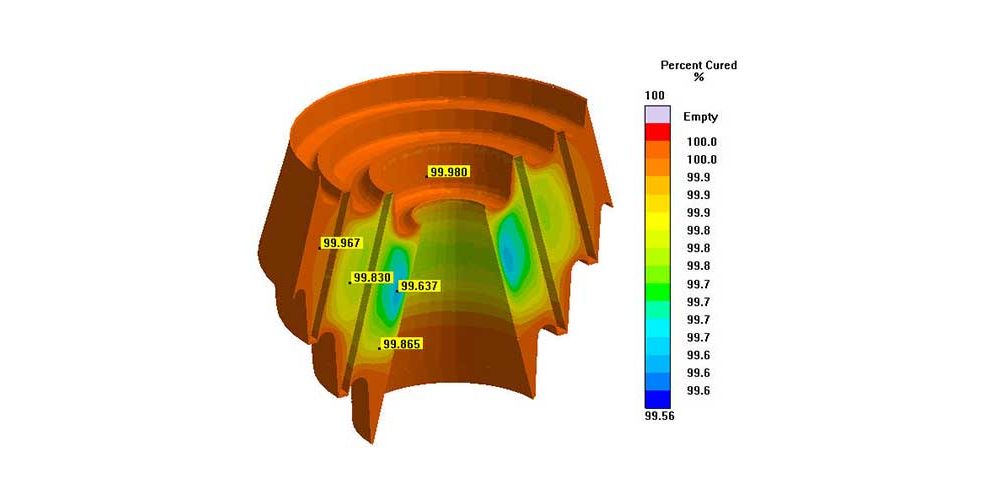

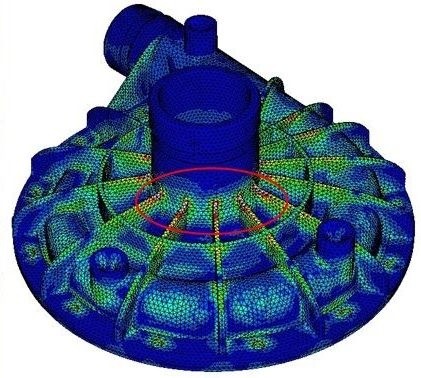

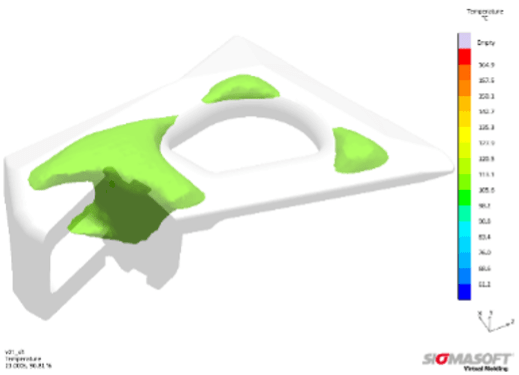

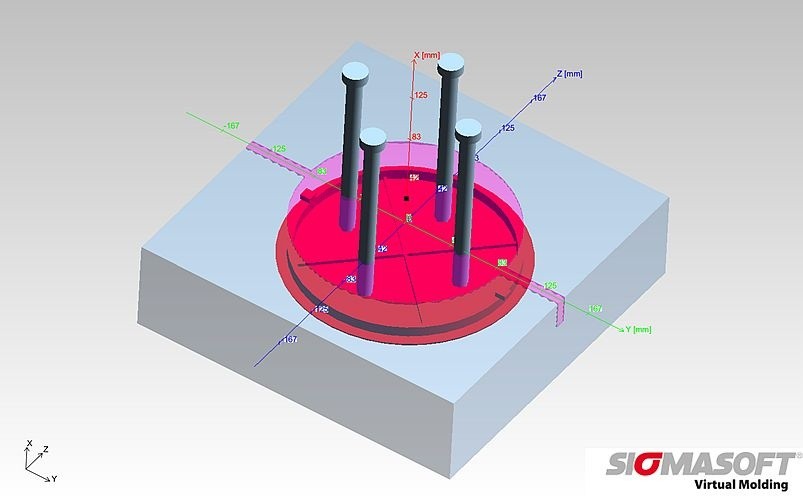

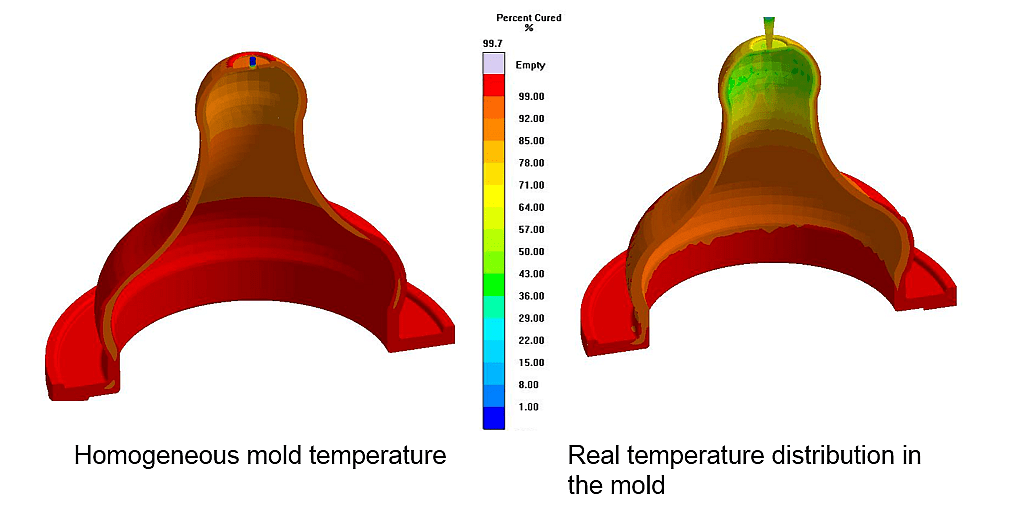

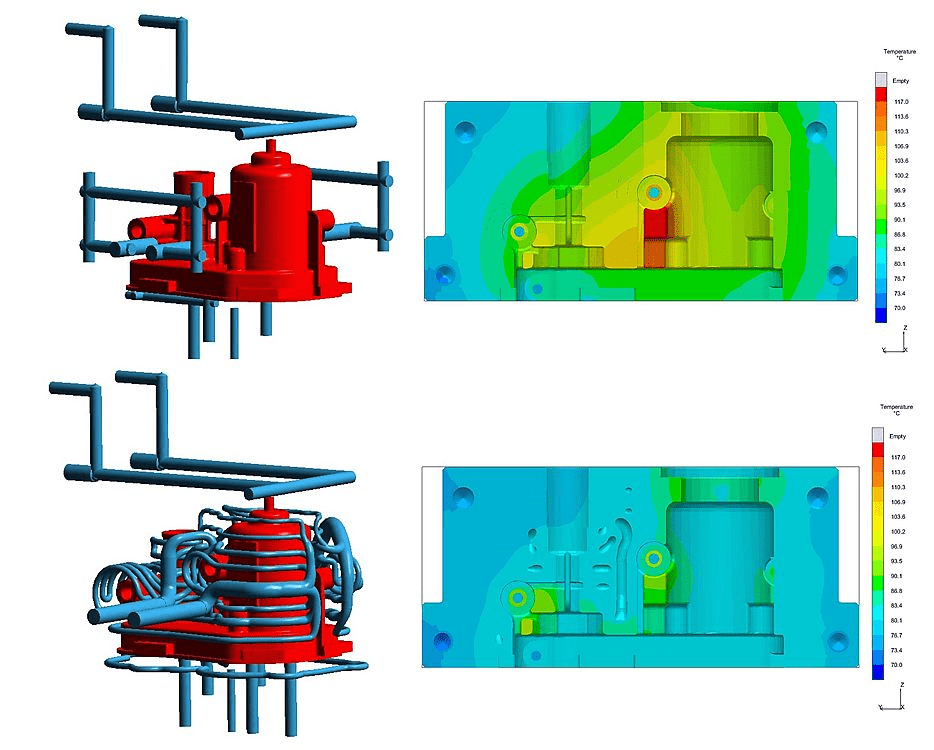

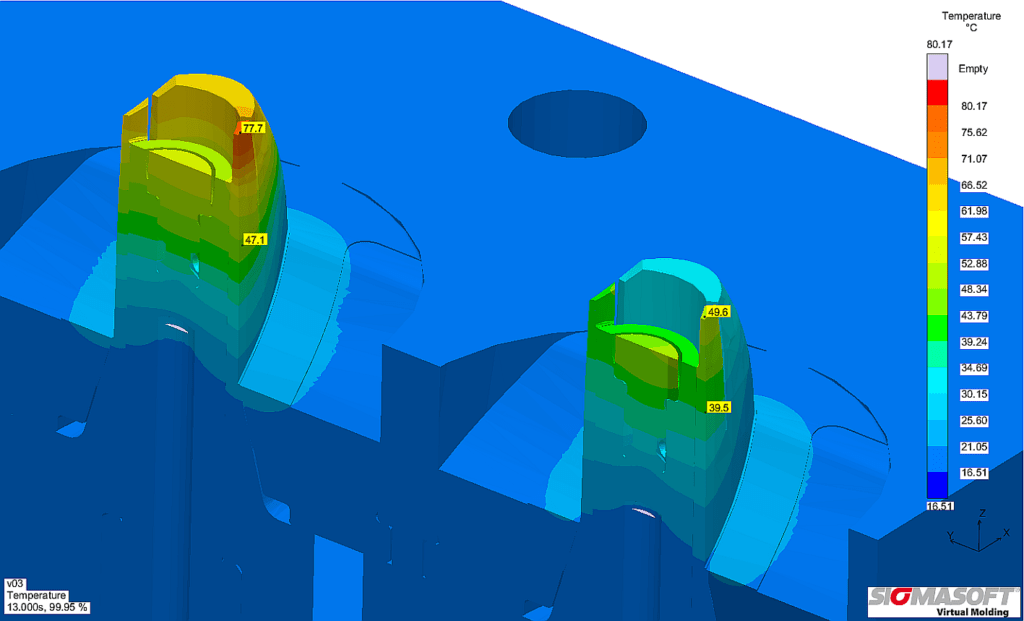

TMT successfully relies on SIGMASOFT® Virtual Molding Vulcanization is the most important step in the manufacturing and processing of rubber products. Vulcanization time directly affects the performance of the final product. Compared with a conventional simulation, SIGMASOFT® Virtual Molding can better predict the vulcanization time of rubber and reduce the number of production trials and the cost …