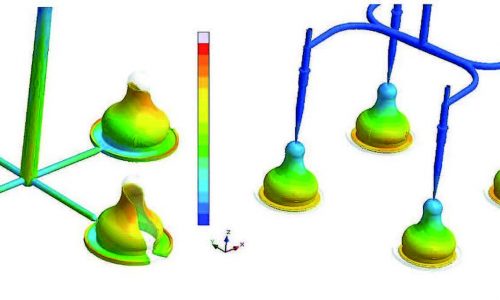

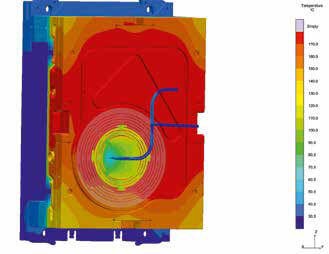

Upfront mold optimization for LSR applications with virtual molding In a four-cavity LSR mold, CVA Silicones,from France, was able to reduce scrap production, optimize thermal layout and avoid costly quality issues by using virtual molding software.

As LIM processes can be quite challenging a thorough understanding of not only the part, but of the whole mold and process are essential for molders to stay competitive. With the help of the Virtual Molding approach one can look into the process upfront and make secure decisions on material, mold and process.

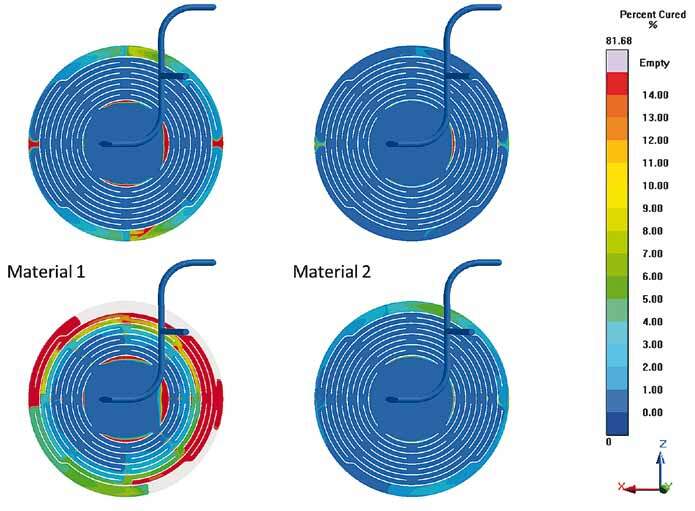

Together with partners Momentive and CVA Silicone, Sigma Engineering demonstrated at Fakuma 2015 how processors can prepare themselves to face the challenges in LSR processing. Besides the choice of the right material the process window definition has a major role to avoid problems in production. Sigmasoft Virtual Molding supports the molder with its improved material database, among other things, which includes a number of LSR data from v5.1 and on.