Thermoplastic

25 Years of Plastic Simulation

SIGMA Engineering proudly continues what the founding fathers of the plastic simulation industry started more 25 years ago, developing software which will serve the polymer injection moulding industry creating better products, better moulds and better processes through capturing plastic phenomena.

The Fastest Way From Design to Delivery

The fastest way to get from design to delivery, SIGMASOFT® Virtual Molding replaces live trials by optimizing the part design, mold design and molding process. We believe that quality and delivery should not be compromised by product complexity.

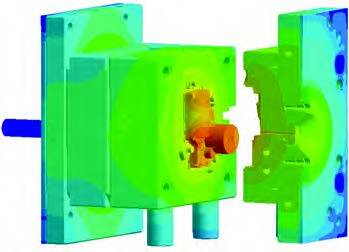

Properly Cooled by Design

Besides the part geometry, 3-D injection molding simulation now also takes into account other factors promoting the efficient design of injection molds and assisting process control during production. A case study makes clear the benefit of process-oriented simulation with the example of a decision in favor of a cooling concept tailored to requirements.

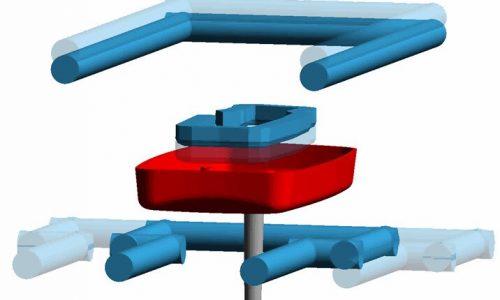

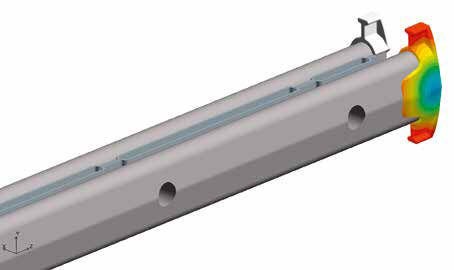

Benefits of Conformal Cooling

The thermal layout of a mold can be optimized during the tooling design, understanding the effect the cooling channel size and location has on the part solidification and deformation. Using SIGMASOFT® Virtual Molding, which works like a virtual injection molding machine, it is possible to visualize the outcome of different concepts and evaluate the potential advantages of more expensive approaches, such as conformal cooling, before the mold design is finalized.

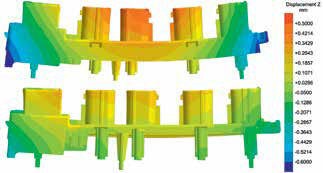

Countering Component Distortion with Perspective

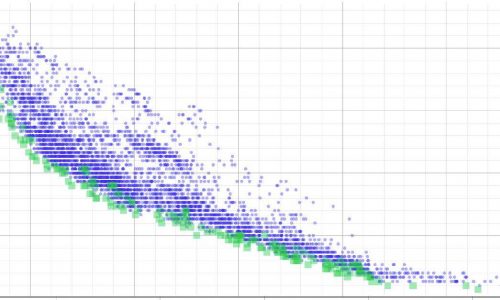

During the manufacturing of complex injection molded parts, component distortion is frequently accepted as a matter of fact. A comparison of simulated distortion results with real component distortion shows that this is not necessarily so. Studies with an electric component revealed a concordance of 90%.

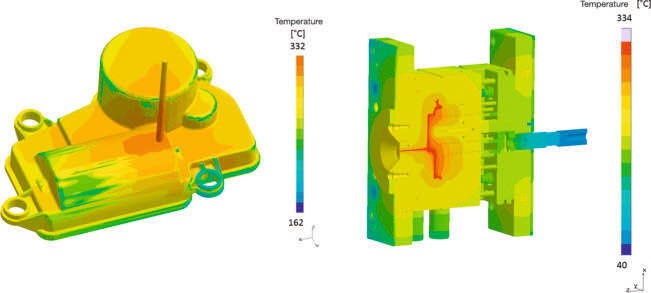

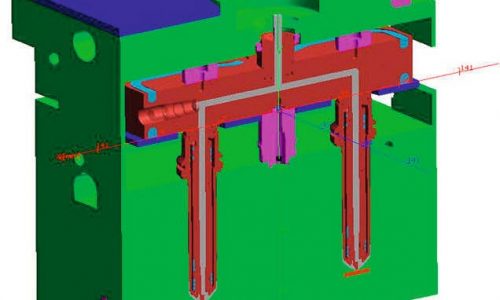

Effect of the Hot Runner on the Mold Cooling

Although hot-runner systems have a considerable influence on the productivity of injection molding processes, they are often neglected in injection molding simulations. How can the simulation only focus on the plastic article and not consider factors of influence on article quality, process stability, and value creation?

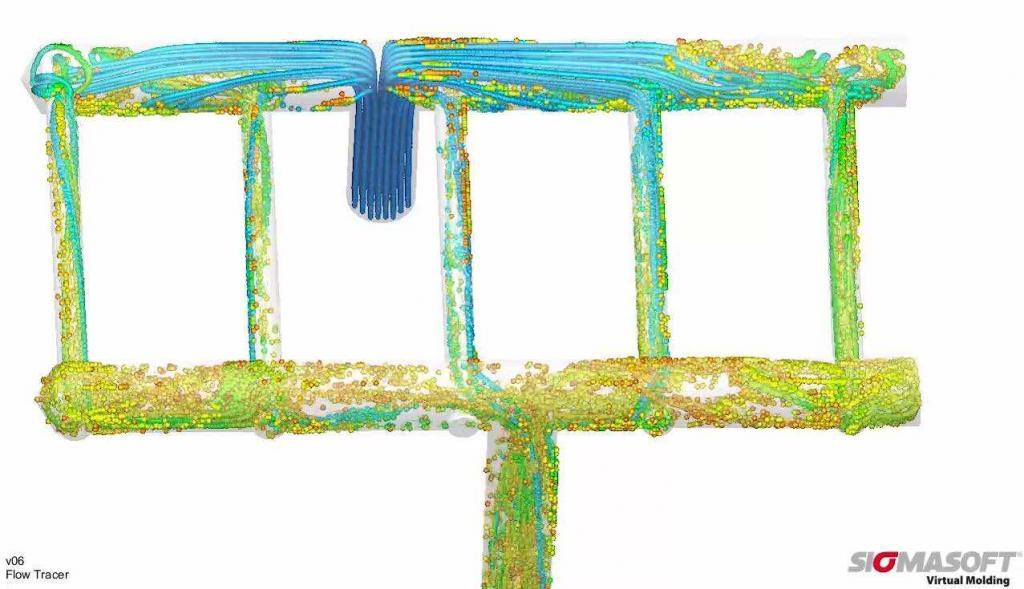

Getting Warpage under Control

The virtual modeling of the injection molding process with Sigmasoft® Virtual Molding provides realistic temperatures in the part and mold.This helps in all stages of the part and process development to avoid mistakes and to save resources, because iterations can be performed within a matter of hours on the computer.

Virtual injection molding: Simulation offers more than flow analysis

Sigmasoft Virtual Molding uses a completely 3D-approach and the integration of a highly developed thermal solver, the injection molding simulation software allows the calculation of multiple consecutive production cycles, considering the thermal interactions throughout all the components in the mold. The accuracy of the entire simulation is thus dramatically increased.