SIGMASOFT® in a new design and with additional functions

New usability concept, new service, new homepage and communication with injection molding machine

SIGMA Engineering GmbH releases the newest version of SIGMASOFT® Virtual Molding on

K-show 2022 including new features. Through the new service Virtual Thermoplastics, problems with material datasets are over and a new interface allows easy data exchange with the molding machine – all presented in a new design.

Aachen, 26.08.2022 – On K 2022 in Duesseldorf (October 19-26th 2022) SIGMA Engineering GmbH presents the new version SIGMASOFT® 6.0 at booth B29 in hall 13. On the stand, visitors get exclusive impressions of the new user interface and implementations of different practical application examples. One of the exhibits shows the direct data exchange between SIGMASOFT® and modern injection molding machines in real-time.

Technical software naturally focuses on mathematical and physical laws and models and the correct calculation and/or simulation. In the research and development of complex software, user-friendliness and boundaryless intuitive usability has only second priority. SIGMA therefore especially focused on usability and completely reworked the concept of the user interface. Improved performance and newly integrated material datasets also facilitate working with SIGMASOFT®.

Though SIGMASOFT® includes an excellent material database, sometimes the precision of the data is not sufficient to achieve a complete match between simulation and reality. Their underlying measurements are often older and describe the behavior in a lab environment rather than during processing. Since each material behaves differently, in reality, depending on part and process, the available datasets are not always precise enough. With „Virtual Thermoplastics“, SIGMA introduces a new service. Through Virtual Thermoplastics a digital fingerprint of the polymer is taken. It allows to identify yet unknown material properties, predict the processing behavior more accurately, and make SIGMASOFT® simulation results even more reliable.

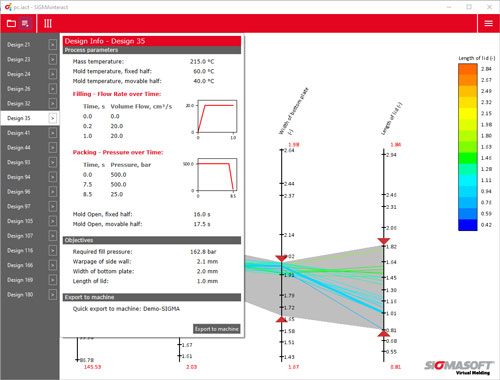

A new interface for direct data import and export between simulation and injection molding machines was developed in cooperation with KraussMaffei. Showcased is the example of a foldable box, used in the transportation of fresh food, made from different recycled POs. The interface allows bidirectional communication: either the targeted geometry from the SIGMASOFT® DoE is selected and sent to the machine with SIGMAinteract® or the process parameters from the current cycle are sent to the software for the next simulation. This data transfer takes place using socialProduction from KraussMaffei. SIGMA showcases a working model of the connected machine control unit while the process runs in reality at KraussMaffei in hall 15 at stand C24 - D24.