The Next Project with SIGMASOFT®

During the development process of your thermoset parts, a number of tasks come your way. The design concept is followed by the mold concept and the process window:

- Positioning, number and power of the heating cartridges

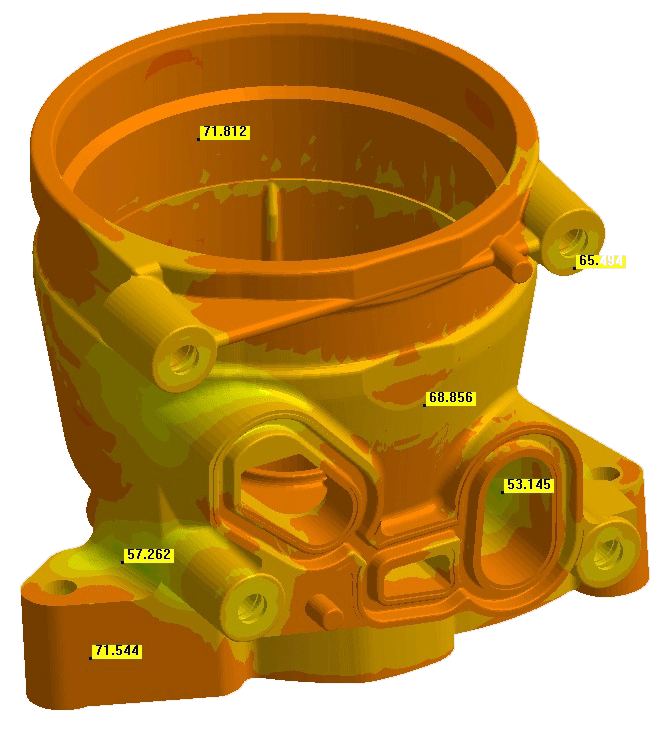

- Identification of cold spots and optimization of heating time

- Effectiveness check of thermal separation between cold runner and cavity

- Temperature sensor positioning

- Time pressure

- Etc.

You are a professional and your tasks are a part of you. We bring you one step ahead. SIGMASOFT® supports you in your work with thermoset materials, whether free-flowing, BMC, or molding resin and in injection molding, transfer molding, or compression molding. Simulate the filling and curing process, calculate jetting and block shear flow and take a look inside your mold before it is built. This provides a reliable basis for your decisions during the development process.Save time, correction loops, money, and experience how effortless a project can run.

SIGMASOFT® VIRTUAL MOLDING SUPPORTS SOLVING COMPLEX CHALLENGES IN INJECTION MOLDING FROM DESIGN TO PROCESSING.

WHAT YOU CAN EXPECT FROM SIGMASOFT®thermoset:

- Predict filling behavior, flow front considering fountain flow, block shear flow and jetting effects

- Fiber orientation of fiber-reinforced materials

- Calculation of curing and scorch

- The exothermic influences during curing reaction on temperature distribution, the effect of curing degree on viscosity

- Heating time and degree of curing for each area of the molded part

- Locate air pockets, determine pressure requirements, and design cold runner

- Simulate electrical heating of the mold considering coupled PID controllers

- Effects of preheating of inserts and material selection on curing behavior, post-curing by tempering processes

SIGMASOFT® guides or accompanies you step by step through the preparation of you simulation project. You virtually create the same process conditions as on your machine and run several production cycles. Accelerate your development process and achieve the desired quality from the very first component.

START VIRTUAL SERIES PRODUCTION EVEN BEFORE YOUR TOOL is BUILT.

MAKE SIGMASOFT® YOUR TOOL AND...

... YOU WILL GET MORE OUT OF YOUR PROJECTS!

OUR IN-HOUSE DEVELOPMENT AND the TEAM OF HIGHLY QUALIFIED ENGINEERS IS THE SERVICE WE PROVIDE TO YOU!

Successful injection molding simulation requires the direct contact between the users and a competent engineering team. Therefore, our solution service, our customer support as well as our application-oriented software developers work closely together with you for your success!

SIGMASOFT®

thermoset INFORMATION FOR YOU TO DOWNLOAD!

ALL INFO IN ONE DOCUMENT.

YOUR INSIGHT INTO OUR CASE STUDIES:

Casestudy

IMPROVED COOLING IN THERMOSET MOLDING SAVES 30,000€ A YEAR IN ONE SINGLE PROJECT