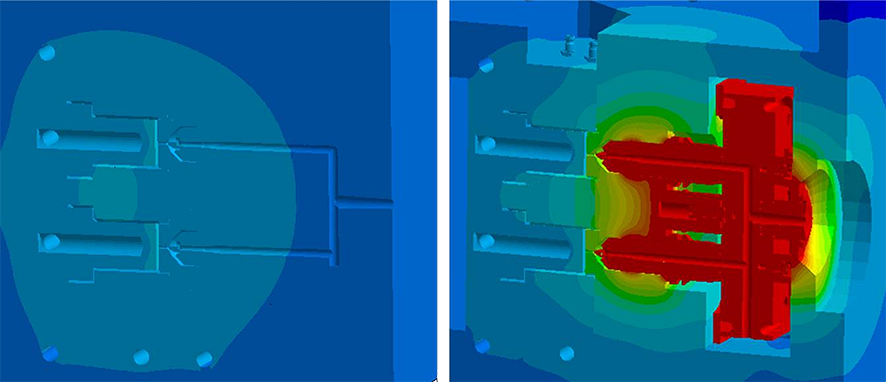

In injection molding simulation, a realistic computation of the temperature distribution in hot-runner molds means taking into account not only the mold components, but also the geometries and materials of the hot runner. After all, it is only with a correct simulation of the thermal state of the cavity and the entire mold that a realistic rheological analysis of the injection molding process can be made and detailed information provided about the thermal relationships in the mold. However, the complete hot-runner geometries are only rarely available. The hot runner is therefore usually completely neglected in the simulation and at best replaced by an idealized runner. However, this major oversimplification has an effect not only on the thermal situation in the mold, but also reduces the value of the prediction of quality and properties of the part.

No Reliable Prediction

Complete neglect of the hot-runner system would only be permissible on the assumption that the hot runner has no significant effect on the mold thermal balance and does not heat up the mold at any point, or otherwise influence it. Apart from that, the user would also have to assume that neither pressure losses nor shear heating take place in the melt channel, so that these effects are not relevant for the simulation.

But every practitioner knows that this is not the case and the hot runner, its components and controller significantly influence the actual process and the article properties. Simulations that do not precisely take into account the hot-runner system therefore cannot provide realistic results for filling pattern, pressure demand and temperature distribution – significant differences between the simulation and reality occur, in particular regarding the holding pressure effect, clamping force, cooling time, shrinkage and warpage. On this basis, it is impossible to make a reliable prediction of the process and part quality.

Hot-runner manufacturers – for understandable reasons – do not make their precise system set-up available in detail as a CAD record. But what possibilities are there for improving the results of the injection molding simulation without a detailed knowledge of the hot-runner geometry? But, between the two extremes of completely taking into account all components and materials, on the one hand, and the vast oversimplification of an idealized runner on the other hand, various intermediate solutions are feasible. Thus, an improved computation of the pressure demand is already possible with a fast 3-D flow simulation of the adiabatic melt channel. The heat that is input by the hot-runner system, and its influence, e.g., on the warpage of the plastic article, can already be represented using the data on the hot-runner system that are available as standard, and a Sigmasoft Multi-Cycle Analysis (software supplier: Sigma Engineering GmbH, Aachen, Germany), as is shown below.

The Question of the Pressure Loss

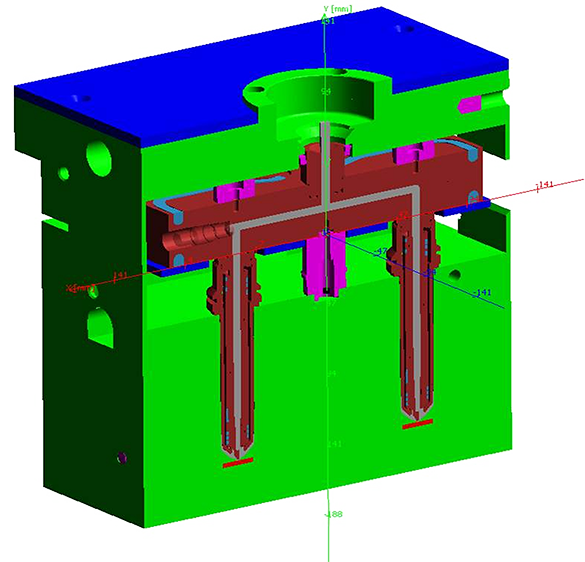

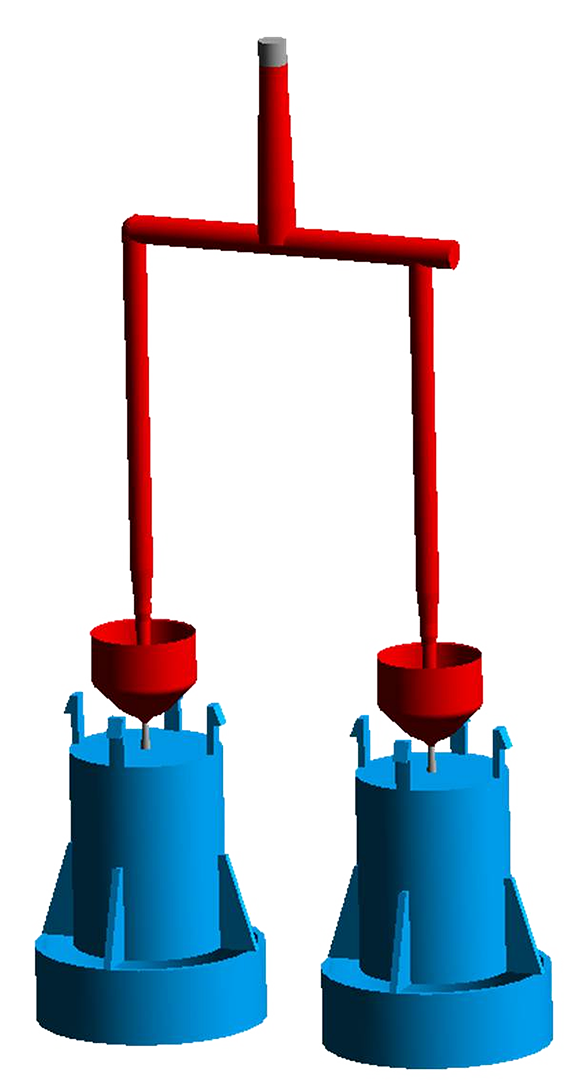

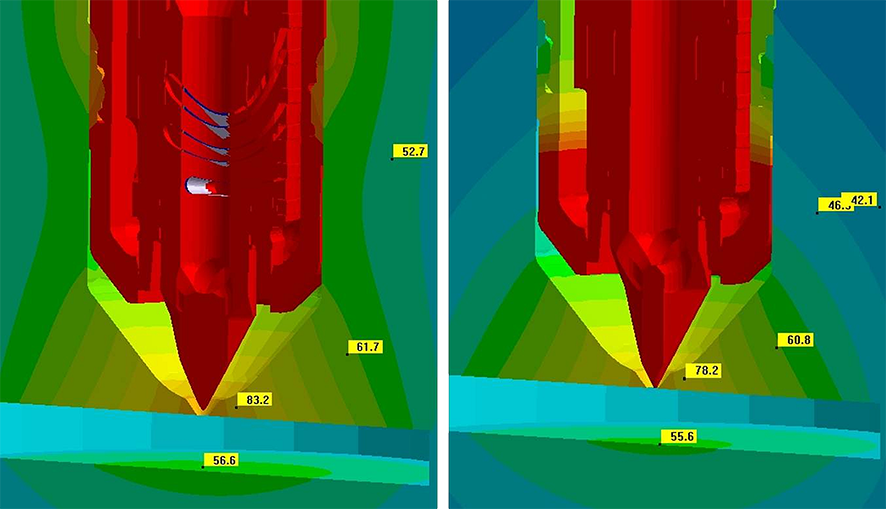

A particular application often requires a fast and accurate prediction of the pressure demand, for example to allow the possible number of cavities or the size of the injection molding machine to be determined. While the pressure loss of the cavities is usually known from previous injection molding simulations, the question of the total pressure loss arises, which depends on the chosen hot-runner system. The hot-runner manufacturer usually makes the actual melt runner, comprising manifold and nozzles, available as a CAD record (Fig.1). Considering this melt channel as adiabatic in the simulation, i.e. virtually isolating it with respect to the mold, is a quick and simple way of improving the predictive power of the simulation.